Table of Contents

Benefits of Using Lifting Equipment in Freight Yard Factories

Lifting equipment plays a crucial role in the efficient operation of freight yard factories. These facilities are responsible for handling and moving large quantities of goods and materials, making the use of lifting equipment essential for ensuring smooth and safe operations. In this article, we will explore the benefits of using lifting equipment in freight yard factories.

One of the primary benefits of using lifting equipment in freight yard factories is increased efficiency. By using specialized lifting equipment such as cranes, forklifts, and hoists, workers can quickly and safely move heavy loads from one location to another. This not only speeds up the handling process but also reduces the risk of injuries and accidents that can occur when lifting heavy objects manually.

In addition to improving efficiency, lifting equipment also helps to maximize the use of available space in freight yard factories. By using equipment such as overhead cranes and stackers, workers can stack goods and materials vertically, allowing for more efficient use of floor space. This is particularly important in freight yard factories where space is often limited, and maximizing storage capacity is essential for meeting production demands.

Furthermore, lifting equipment helps to improve workplace safety in freight yard factories. Manual lifting of heavy objects can lead to musculoskeletal injuries and strains, putting workers at risk of long-term health problems. By using lifting equipment, workers can avoid these risks and ensure their safety while handling heavy loads. Additionally, lifting equipment is designed with safety features such as overload protection and emergency stop buttons, further reducing the risk of accidents in the workplace.

Another benefit of using lifting equipment in freight yard factories is the ability to handle a wide range of loads. Different types of lifting equipment are available to handle various sizes and weights of goods and materials, allowing workers to efficiently move everything from small packages to large containers. This versatility makes lifting equipment a valuable asset in freight yard factories where a diverse range of goods and materials are handled on a daily basis.

Moreover, lifting equipment helps to reduce labor costs in freight yard factories. By automating the lifting and moving of heavy loads, workers can focus on other tasks that require human intervention, such as quality control and inventory management. This not only increases productivity but also reduces the need for additional labor, resulting in cost savings for the factory.

In conclusion, the benefits of using lifting equipment in freight yard factories are numerous. From increased efficiency and space utilization to improved safety and versatility, lifting equipment plays a vital role in ensuring the smooth operation of these facilities. By investing in quality lifting equipment, freight yard factories can enhance their productivity, reduce labor costs, and create a safer working environment for their employees.

Types of Lifting Equipment Suitable for Freight Yard Factories

Lifting equipment plays a crucial role in the efficient operation of freight yard factories. These facilities are responsible for handling and moving large quantities of goods and materials, making the use of appropriate lifting equipment essential. There are several types of lifting equipment that are suitable for use in freight yard factories, each with its own unique capabilities and advantages.

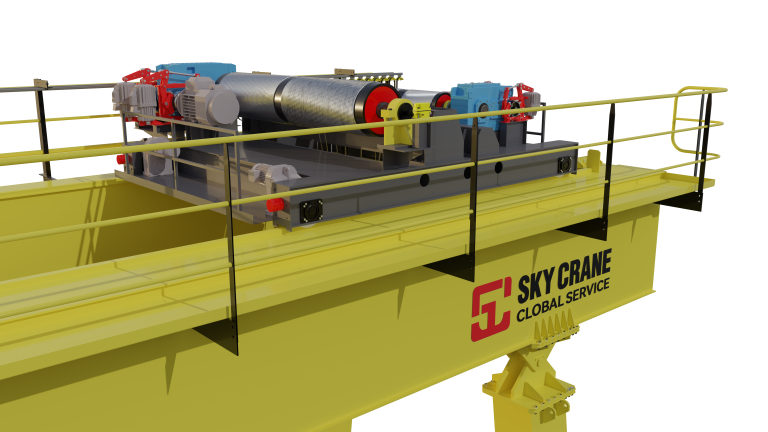

One of the most common types of lifting equipment used in freight yard factories is the overhead crane. Overhead cranes are typically mounted on tracks that run along the ceiling of the facility, allowing them to move horizontally and vertically to lift and transport heavy loads. These cranes are ideal for lifting and moving large, bulky items such as shipping containers, machinery, and raw materials. Overhead cranes are available in various configurations, including single girder, double girder, and gantry cranes, each designed to meet specific lifting requirements.

Another type of lifting equipment commonly used in freight yard factories is the forklift. Forklifts are versatile machines that are capable of lifting and transporting heavy loads over short distances. They are often used to load and unload trucks, stack pallets, and move materials around the facility. Forklifts come in various sizes and configurations, including electric, gas, and diesel-powered models, each suited to different applications and operating environments.

In addition to overhead cranes and forklifts, freight yard factories may also utilize other types of lifting equipment, such as hoists, jib cranes, and scissor lifts. Hoists are mechanical devices that are used to lift and lower loads vertically, making them ideal for tasks such as loading and unloading trucks or moving materials to different levels within the facility. Jib cranes are similar to overhead cranes but are mounted on a vertical mast, allowing them to rotate and reach areas that are not easily accessible by other types of lifting equipment. Scissor lifts are hydraulic platforms that can be raised and lowered to different heights, making them useful for tasks such as maintenance work or accessing elevated storage areas.

When selecting lifting equipment for a freight yard factory, it is important to consider factors such as the type and weight of the loads to be lifted, the layout of the facility, and the operating environment. It is also essential to ensure that the equipment meets all safety and regulatory requirements to prevent accidents and injuries. Regular maintenance and inspections should be conducted to ensure that the equipment is in good working condition and to identify any potential issues before they become a safety hazard.

In conclusion, there are several types of lifting equipment that are suitable for use in freight yard factories, each with its own unique capabilities and advantages. Overhead cranes, forklifts, hoists, jib cranes, and scissor lifts are just a few examples of the equipment that may be used to lift and transport heavy loads in these facilities. By selecting the right type of lifting equipment and ensuring that it is properly maintained and operated, freight yard factories can improve efficiency, productivity, and safety in their operations.

Safety Measures When Operating Lifting Equipment in Freight Yard Factories

Lifting equipment plays a crucial role in the operations of freight yard factories, as it is used to move heavy loads and materials efficiently and safely. However, operating lifting equipment comes with its own set of risks and hazards that need to be carefully managed to ensure the safety of workers and the smooth running of operations.

One of the most important safety measures when operating lifting equipment in freight yard factories is proper training. Workers who operate lifting equipment must be adequately trained on how to use the equipment safely and effectively. This includes understanding the equipment’s capabilities and limitations, as well as how to perform routine maintenance and inspections to ensure it is in good working condition.

In addition to training, it is essential for workers to follow all safety procedures and guidelines when operating lifting equipment. This includes wearing appropriate personal protective equipment, such as hard hats, gloves, and safety goggles, to protect themselves from potential hazards. Workers should also be aware of their surroundings and ensure that the area is clear of obstacles and other workers before operating the equipment.

Regular inspections and maintenance of lifting equipment are also critical to ensuring its safe operation. Equipment should be inspected before each use to check for any signs of damage or wear that could affect its performance. Any issues should be addressed promptly to prevent accidents or injuries. Routine maintenance should also be performed to keep the equipment in good working condition and prevent breakdowns.

Another important safety measure when operating lifting equipment in freight yard factories is proper communication. Workers should communicate effectively with each other to coordinate lifts and ensure that everyone is aware of the plan and their role in the operation. Clear communication can help prevent accidents and ensure that lifts are carried out safely and efficiently.

It is also essential for workers to be aware of the weight limits of the lifting equipment and to never exceed them. Overloading lifting equipment can cause it to malfunction or fail, leading to accidents and injuries. Workers should always check the weight of the load before lifting it and make sure it is within the equipment’s capacity.

| Nr. | Commodity Name |

| 1 | LD electric single beam crane |

| 2 | Semi – gantry Crane |

| 3 | European-style crane |

| 4 | Harbour crane |

Proper storage of lifting equipment when not in use is another important safety measure in freight yard factories. Equipment should be stored in a designated area that is secure and free from hazards. This can help prevent accidents and damage to the equipment, as well as ensure that it is ready for use when needed.

In conclusion, safety measures when operating lifting equipment in freight yard factories are essential to protect workers and ensure the smooth running of operations. Proper training, following safety procedures, regular inspections and maintenance, effective communication, and proper storage are all critical to ensuring the safe operation of lifting equipment. By following these safety measures, workers can minimize the risks and hazards associated with operating lifting equipment and create a safe working environment in freight yard factories.