Table of Contents

Electric Chain Crane Safety Standards

Electric chain cranes are essential tools in various industries, facilitating the lifting and movement of heavy loads with efficiency and precision. However, the operation of these cranes comes with inherent risks, necessitating the establishment of stringent safety standards to protect both operators and bystanders. Understanding these safety standards is crucial for companies that utilize electric chain cranes, as adherence not only ensures compliance with legal regulations but also promotes a culture of safety within the workplace.

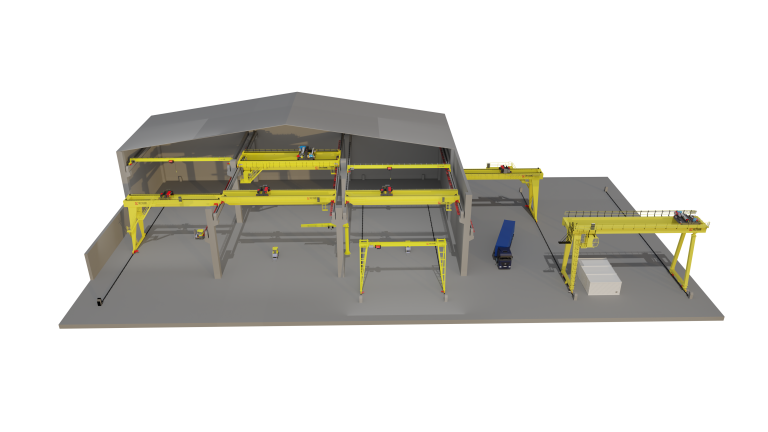

| Nr. | Article Name |

| 1 | LD electric single beam crane |

| 2 | Universal gantry crane |

| 3 | European-style crane |

| 4 | Harbour crane |

To begin with, the safety standards for electric chain cranes are often dictated by national and international organizations, such as the Occupational Safety and Health Administration (OSHA) in the United States and the International Organization for Standardization (ISO). These organizations provide guidelines that cover various aspects of crane operation, including design, maintenance, and operator training. For instance, OSHA mandates that all lifting equipment, including electric chain cranes, must be inspected regularly to ensure they are in safe working condition. This includes checking for wear and tear on the chain, hoist, and other critical components, as well as ensuring that safety devices, such as limit switches and emergency stop buttons, are functioning correctly.

Moreover, operator training is a fundamental component of electric chain crane safety standards. Companies are required to provide comprehensive training programs that equip operators with the necessary skills and knowledge to handle the equipment safely. This training typically covers the proper use of the crane, load handling techniques, and emergency procedures. By ensuring that operators are well-trained, companies can significantly reduce the likelihood of accidents and injuries associated with crane operation. Additionally, refresher courses are often recommended to keep operators updated on the latest safety practices and technological advancements in crane operation.

In addition to operator training, the implementation of safety protocols is vital for minimizing risks. Companies should establish clear guidelines regarding the maximum load capacity of electric chain cranes, as exceeding this limit can lead to catastrophic failures. Furthermore, it is essential to conduct risk assessments to identify potential hazards in the work environment. This proactive approach allows companies to implement control measures, such as the use of barriers or warning signs, to mitigate risks associated with crane operation.

Another critical aspect of electric chain crane safety standards is the importance of personal protective equipment (PPE). Operators and personnel working in proximity to the crane should be equipped with appropriate PPE, such as hard hats, safety glasses, and steel-toed boots. This protective gear serves as a first line of defense against potential injuries resulting from falling objects or accidental contact with moving parts.

Furthermore, regular maintenance and servicing of electric chain cranes are essential to ensure their safe operation. Companies should establish a maintenance schedule that includes routine inspections and servicing by qualified personnel. This practice not only extends the lifespan of the equipment but also helps identify and rectify potential issues before they escalate into serious problems.

In conclusion, electric chain crane safety standards are critical for ensuring the safe operation of these powerful lifting devices. By adhering to established guidelines, providing thorough training for operators, implementing safety protocols, and maintaining equipment diligently, companies can create a safer work environment. Ultimately, prioritizing safety not only protects employees but also enhances operational efficiency and productivity, contributing to the overall success of the organization.

Innovations in Electric Chain Crane Technology

The landscape of electric chain crane technology has undergone significant transformations in recent years, driven by advancements in engineering, materials science, and automation. As industries increasingly seek to enhance efficiency and safety in material handling, electric chain crane companies are at the forefront of these innovations, developing solutions that not only meet but exceed the demands of modern operations. One of the most notable advancements is the integration of smart technology into electric chain cranes. This includes the incorporation of sensors and IoT (Internet of Things) capabilities, which allow for real-time monitoring of crane performance and load conditions. By utilizing these technologies, operators can gain valuable insights into the operational status of the crane, enabling predictive maintenance and reducing downtime. Consequently, this leads to increased productivity and cost savings for businesses.

Moreover, the development of advanced control systems has revolutionized the way electric chain cranes are operated. With the advent of sophisticated software and user-friendly interfaces, operators can now manage cranes with greater precision and ease. These systems often feature programmable settings that allow for customized lifting operations, which can be particularly beneficial in environments where different loads and lifting requirements are common. As a result, the flexibility offered by these innovations not only enhances operational efficiency but also improves safety by minimizing the risk of human error.

In addition to smart technology and advanced control systems, electric chain crane companies are also focusing on improving the energy efficiency of their products. The push for sustainability has led to the development of cranes that utilize energy-efficient motors and regenerative braking systems. These innovations not only reduce energy consumption but also lower operational costs, making electric chain cranes a more environmentally friendly option compared to traditional lifting equipment. Furthermore, the use of lightweight materials in crane construction has contributed to enhanced energy efficiency, as lighter cranes require less power to operate, thereby reducing their overall carbon footprint.

Another significant trend in electric chain crane technology is the emphasis on modular design. This approach allows for greater customization and scalability, enabling companies to adapt their lifting solutions to specific operational needs. Modular cranes can be easily reconfigured or expanded, which is particularly advantageous in dynamic work environments where requirements may change frequently. This adaptability not only maximizes the utility of the equipment but also extends its lifespan, as components can be upgraded or replaced without the need for a complete overhaul.

As electric chain crane companies continue to innovate, safety remains a paramount concern. The introduction of enhanced safety features, such as overload protection systems and emergency stop mechanisms, has become standard in modern electric chain cranes. These features are designed to prevent accidents and ensure the well-being of operators and personnel in the vicinity. Additionally, training programs that incorporate virtual reality simulations are being developed to provide operators with a safe and effective way to learn how to handle cranes, further promoting a culture of safety within the industry.

In conclusion, the innovations in electric chain crane technology reflect a broader trend towards increased efficiency, safety, and sustainability in material handling. As electric chain crane companies continue to push the boundaries of what is possible, the future of lifting equipment looks promising. With smart technology, advanced control systems, energy-efficient designs, modular construction, and enhanced safety features, electric chain cranes are poised to play a crucial role in the evolution of industrial operations, meeting the challenges of today while paving the way for a more efficient and sustainable tomorrow.

Top Electric Chain Crane Manufacturers in the Industry

In the realm of material handling and industrial lifting solutions, electric chain cranes have emerged as indispensable tools, facilitating the efficient movement of heavy loads in various sectors. As industries continue to evolve, the demand for reliable and high-performance electric chain cranes has surged, prompting numerous manufacturers to innovate and enhance their offerings. Among the leading players in this competitive landscape, several companies stand out due to their commitment to quality, technological advancement, and customer satisfaction.

One of the foremost manufacturers in the electric chain crane sector is Konecranes, a global leader known for its extensive range of lifting equipment. With a strong emphasis on safety and reliability, Konecranes has developed electric chain cranes that incorporate advanced features such as smart technology and real-time monitoring systems. These innovations not only enhance operational efficiency but also ensure that users can manage their lifting tasks with confidence. Furthermore, Konecranes\\u2019 commitment to sustainability is evident in its efforts to produce energy-efficient cranes that minimize environmental impact while maximizing performance.

Another prominent name in the industry is Demag, a subsidiary of Terex Corporation, which has a rich history of engineering excellence. Demag electric chain cranes are renowned for their robust construction and precision engineering, making them suitable for a wide range of applications, from manufacturing to warehousing. The company\\u2019s focus on customization allows clients to tailor their cranes to specific operational needs, thereby enhancing productivity. Additionally, Demag\\u2019s dedication to after-sales support ensures that customers receive ongoing assistance, further solidifying their reputation as a trusted manufacturer.

In addition to Konecranes and Demag, Yale, a brand under the umbrella of the Columbus McKinnon Corporation, has made significant strides in the electric chain crane market. Yale\\u2019s electric chain hoists and cranes are designed with user-friendly features that simplify operation and maintenance. The company\\u2019s commitment to innovation is reflected in its development of lightweight yet durable cranes that can handle substantial loads with ease. Moreover, Yale\\u2019s focus on safety is paramount, as evidenced by their incorporation of advanced safety features that protect both operators and equipment.

Similarly, the Japanese manufacturer Hitachi has carved a niche for itself in the electric chain crane industry. Known for its cutting-edge technology and engineering prowess, Hitachi offers a range of electric chain cranes that are both efficient and reliable. The company\\u2019s emphasis on research and development has led to the creation of cranes that not only meet but often exceed industry standards. Hitachi\\u2019s global presence and commitment to quality have made it a preferred choice for many businesses seeking dependable lifting solutions.

Furthermore, the German company Stahl CraneSystems is recognized for its high-quality electric chain hoists and cranes. Stahl\\u2019s products are characterized by their durability and versatility, making them suitable for various industrial applications. The company\\u2019s focus on modular design allows for easy integration into existing systems, providing customers with flexibility and adaptability. Stahl\\u2019s dedication to continuous improvement and innovation ensures that its electric chain cranes remain at the forefront of technology.

In conclusion, the electric chain crane market is populated by several key manufacturers, each contributing to the advancement of lifting technology. Companies like Konecranes, Demag, Yale, Hitachi, and Stahl CraneSystems exemplify the qualities of innovation, reliability, and customer-centricity that define the industry. As businesses continue to seek efficient and safe lifting solutions, these manufacturers are well-positioned to meet the evolving demands of the market, ensuring that electric chain cranes remain vital assets in various industrial applications.