Table of Contents

Benefits of Investing in High-Quality Lifting Equipment for Factories

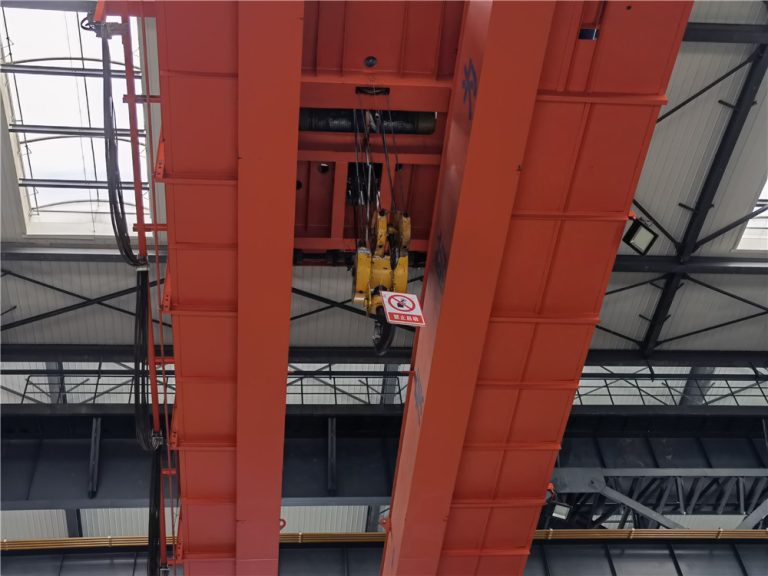

Investing in high-quality lifting equipment for factories can bring numerous benefits to businesses looking to improve efficiency, safety, and productivity in their operations. From overhead cranes to hoists and winches, having the right lifting equipment can make a significant difference in the way goods are handled and moved within a factory setting.

One of the key benefits of investing in high-quality lifting equipment is improved safety. By using equipment that is designed to handle heavy loads safely and efficiently, the risk of accidents and injuries in the workplace can be greatly reduced. High-quality lifting equipment is built to withstand the demands of industrial settings, ensuring that workers can perform their tasks without putting themselves at risk.

In addition to safety, investing in high-quality lifting equipment can also lead to increased productivity. By using equipment that is designed to handle heavy loads with ease, workers can move goods more quickly and efficiently, leading to faster turnaround times and increased output. This can help businesses meet deadlines and fulfill orders in a timely manner, ultimately improving customer satisfaction and boosting profitability.

Furthermore, high-quality lifting equipment can also help businesses save money in the long run. While the initial investment in quality equipment may be higher than opting for cheaper alternatives, the durability and reliability of high-quality equipment can lead to cost savings over time. By reducing the need for repairs and replacements, businesses can avoid costly downtime and keep their operations running smoothly.

Another benefit of investing in high-quality lifting equipment is improved versatility. With a wide range of lifting equipment available on the market, businesses can choose equipment that is tailored to their specific needs and requirements. Whether it’s a gantry crane for heavy lifting or a jib crane for more precise movements, businesses can find equipment that meets their unique challenges and helps them optimize their operations.

Moreover, high-quality lifting equipment can also help businesses comply with industry regulations and standards. By using equipment that meets or exceeds safety requirements, businesses can ensure that they are operating in accordance with legal guidelines and best practices. This can help prevent fines and penalties, as well as protect the reputation of the business in the eyes of customers and stakeholders.

In conclusion, investing in high-quality lifting equipment for factories can bring a wide range of benefits to businesses looking to improve safety, productivity, and efficiency in their operations. From improved safety and productivity to cost savings and compliance with regulations, the advantages of investing in quality lifting equipment are clear. By choosing equipment that is built to last and designed to meet the demands of industrial settings, businesses can set themselves up for success and ensure the smooth operation of their operations for years to come.

Top Considerations When Choosing Lifting Equipment for Factory Operations

When it comes to running a successful factory operation, having the right lifting equipment is essential. Whether you are lifting heavy machinery, materials, or products, having the proper equipment can make a significant difference in efficiency and safety. With so many options available on the market, it can be overwhelming to choose the right lifting equipment for your specific needs. In this article, we will discuss some of the top considerations to keep in mind when selecting lifting equipment for your factory.

One of the first things to consider when choosing lifting equipment for your factory is the weight capacity. It is crucial to know the maximum weight that the equipment can safely lift. Exceeding the weight capacity of the equipment can lead to accidents and injuries, so it is essential to choose equipment that can handle the loads you will be lifting on a regular basis.

Another important consideration is the type of lifting mechanism that the equipment uses. There are various types of lifting equipment available, including cranes, hoists, and forklifts, each with its own advantages and disadvantages. It is essential to choose the type of equipment that best suits your specific needs and the layout of your factory.

In addition to weight capacity and lifting mechanism, it is also important to consider the height and reach of the lifting equipment. Depending on the layout of your factory and the height of the items you need to lift, you may need equipment with a longer reach or higher lifting height. It is crucial to choose equipment that can easily reach the areas where you will be lifting items to ensure efficiency and safety.

| Nr. | Product Name |

| 1 | 5~400T NEW-TYPE OVERHEAD CRANE WITH HOOK |

| 2 | Double – girder Gantry Crane |

| 3 | European-style crane |

| 4 | Harbour crane |

Safety is another critical factor to consider when choosing lifting equipment for your factory. It is essential to choose equipment that meets all safety standards and regulations to ensure the safety of your employees and prevent accidents. Look for equipment that is equipped with safety features such as overload protection, emergency stop buttons, and safety guards to minimize the risk of accidents and injuries.

Durability and reliability are also essential factors to consider when choosing lifting equipment for your factory. You want equipment that is built to last and can withstand the rigors of daily use in a factory setting. Look for equipment made from high-quality materials and from reputable manufacturers known for producing reliable and durable equipment.

Cost is another important consideration when choosing lifting equipment for your factory. While it is essential to invest in high-quality equipment that meets your specific needs, it is also important to consider your budget. Compare prices from different manufacturers and suppliers to find equipment that offers the best value for your money.

In conclusion, choosing the right lifting equipment for your factory is essential for ensuring efficiency, safety, and productivity. Consider factors such as weight capacity, lifting mechanism, height and reach, safety features, durability, reliability, and cost when selecting lifting equipment for your factory. By keeping these considerations in mind, you can choose the best lifting equipment for your specific needs and ensure the success of your factory operations.

How Regular Maintenance and Inspections Can Extend the Lifespan of Lifting Equipment in Factories

Lifting equipment plays a crucial role in the day-to-day operations of factories, allowing for the safe and efficient movement of heavy materials and products. However, like any machinery, lifting equipment requires regular maintenance and inspections to ensure it remains in optimal working condition. By implementing a proactive maintenance and inspection schedule, factory owners can extend the lifespan of their lifting equipment, reduce the risk of accidents, and improve overall productivity.

Regular maintenance is essential for keeping lifting equipment in good working order. This includes tasks such as lubricating moving parts, checking for wear and tear, and ensuring all safety features are functioning properly. By addressing minor issues before they escalate into major problems, factory owners can prevent costly downtime and repairs. Additionally, regular maintenance can help identify potential safety hazards, reducing the risk of accidents and injuries in the workplace.

In addition to regular maintenance, factory owners should also schedule routine inspections of their lifting equipment. Inspections should be conducted by qualified professionals who have the knowledge and expertise to identify potential issues and recommend appropriate solutions. During an inspection, the technician will thoroughly examine the equipment, looking for signs of wear, damage, or malfunction. They will also test the equipment to ensure it is operating correctly and safely.

By conducting regular inspections, factory owners can catch potential problems early on and address them before they lead to equipment failure. This proactive approach can help prevent accidents and injuries, as well as minimize downtime and repair costs. In some cases, inspections may be required by law or industry regulations to ensure compliance with safety standards.

When it comes to extending the lifespan of lifting equipment, preventative maintenance is key. By implementing a preventative maintenance program, factory owners can address small issues before they become major problems, prolonging the life of their equipment and maximizing its efficiency. Preventative maintenance may include tasks such as cleaning, lubricating, and adjusting components, as well as replacing worn or damaged parts.

In addition to preventative maintenance, factory owners should also keep detailed records of all maintenance and inspection activities. This documentation can help track the condition of the equipment over time, identify patterns of wear or failure, and make informed decisions about when to repair or replace equipment. By maintaining accurate records, factory owners can ensure their lifting equipment remains in optimal working condition and meets all safety requirements.

In conclusion, regular maintenance and inspections are essential for extending the lifespan of lifting equipment in factories. By implementing a proactive maintenance schedule, factory owners can prevent costly downtime, reduce the risk of accidents, and improve overall productivity. By conducting routine inspections and keeping detailed records, factory owners can ensure their lifting equipment remains in optimal working condition and meets all safety requirements. Investing in regular maintenance and inspections is a smart decision that can pay off in the long run by prolonging the life of lifting equipment and ensuring a safe and efficient workplace.